TIN FREE STEEL

Details:

The manufacturing process of TFS (Tin Free Steel) coils typically involves the following steps:

- *Steel Production*: Raw materials such as iron ore, coal, and limestone are used to produce steel through processes like blast furnaces or electric arc furnaces.

- *Rolling*: The steel is hot rolled into coils of the desired thickness and width. This step may involve multiple passes through rolling mills to achieve the desired dimensions.

- *Annealing*: The rolled steel coils undergo annealing, a heat treatment process, to improve their ductility and formability. This involves heating the steel to high temperatures and then slowly cooling it.

- *Tinning*: In the case of TFS, the steel coils are coated with a thin layer of tin on both sides. This can be achieved through electrolytic deposition, where the steel coil is immersed in an electrolyte solution with dissolved tin, and an electric current is passed through it to deposit tin onto the surface.

- *Passivation*: After tinning, the surface of the steel may be passivated to enhance its corrosion resistance. Passivation involves treating the surface with chemicals or coatings to create a protective layer.

- *Finishing*: The coated steel coils undergo various finishing processes such as trimming, slitting, and recoiling to achieve the final dimensions and surface quality required by customers.

- *Quality Control*: Throughout the manufacturing process, quality control measures are implemented to ensure that the TFS coils meet the required specifications for thickness, coating weight, surface finish, and other properties.

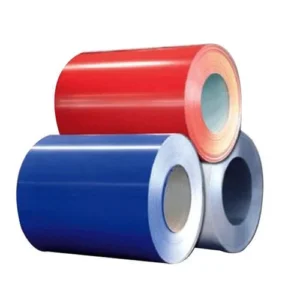

Once the TFS coils are manufactured, they are used in various applications including:

- *Food Packaging*: TFS coils are commonly used to manufacture cans for food and beverages due to their corrosion resistance and ability to preserve the contents.

- *Chemical and Aerosol Packaging*: TFS coils are also used in the production of cans for chemicals, paints, and aerosol products.

- *Battery Casings*: TFS coils are used in the manufacturing of battery casings due to their durability and resistance to corrosion from battery electrolytes.

- *Decorative and Industrial Uses*: TFS coils may also be used for decorative purposes such as metal signage, as well as in industrial applications such as automotive components and household appliances.

Summary

Overall, the manufacturing process of TFS coils involves several steps to produce a corrosion-resistant steel product that finds widespread use in packaging and other industries.

TIN FREE STEEL