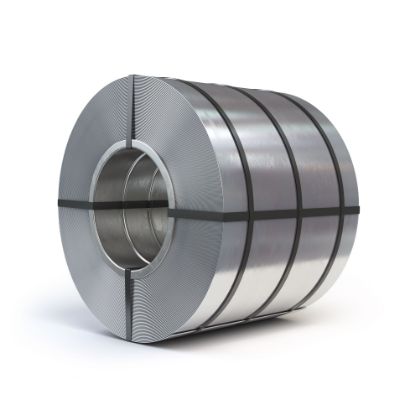

HRC

HOT ROLLED STEEL COILS

Details:

“HRC” typically stands for “Hot Rolled Coil” in the steel industry. Here’s a brief overview of the process from raw materials to finished products and some applications:

- *Raw Materials*: The process starts with raw materials like iron ore, coal, and limestone. These are refined into iron in a blast furnace, which is then further processed in a basic oxygen furnace to produce molten steel.

- *Casting*: The molten steel is cast into large slabs or billets.

- *Rolling*: The slabs or billets are heated and passed through a series of rollers to reduce their thickness and shape them into coils. This process is called hot rolling.

- *Finishing*: The hot rolled coils may undergo further processing such as pickling, annealing, or coating to achieve specific properties or surface finishes

- *Cutting and Forming*: The coils are then cut into sheets or strips of desired lengths and widths. These can be further formed into various shapes using processes like stamping, bending, or welding.

- *Temperature:* The rolling process occurs at temperatures above 1700°F (926°C), which makes the steel more malleable and easier to shape.

- *Thickness Range:* Hot rolled steel coils are available in various thicknesses, ranging from a few millimeters to several centimeters, depending on the application and requirements.

- *Applications:* Commonly used in a variety of industries, including construction, automotive, appliances, and general manufacturing. They are suitable for applications where dimensional tolerances and surface finish are less critical.

- *Strength and Ductility:* Hot rolled steel tends to have higher levels of ductility and toughness compared to cold rolled steel. This makes it suitable for applications that require formability.

- 7. *Cost-Effective:* The production process for hot rolled steel is generally more cost-effective than cold rolling, making it a preferred choice for certain applications where surface finish is not a critical factor.

- *Standards and Specifications:* Hot rolled steel coils are produced according to various standards and specifications set by industry organizations and governments to ensure quality and consistency.

Important Note:

It’s important to note that while hot rolled steel coils have advantages in terms of cost and formability, they may not offer the same surface finish and dimensional precision as cold rolled steel. The choice between hot rolled and cold rolled steel depends on the specific requirements of the intended application.

HRC